Sample Preparation

Our sample preparation services include the production of high-quality polished sections of solid and granular materials in different formats and sizes. We offer a large range of high-quality products using state-of-the-art equipment by Logitech Limited.

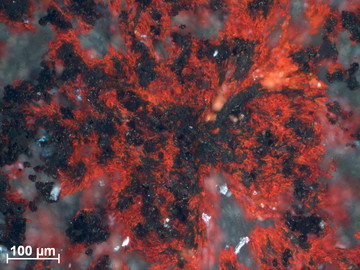

Grain Mount

Granular material (particle sizes between 20 and 2,000 µm) is mixed with synthetic graphite powder and de-agglomerated. The mixture is embedded in epoxy and then cured. Once the resin has cured, the sample block is grinded and polished. Polished sample blocks with diameters 25 mm, 25.4 mm (1 inch), 30 mm and 40 mm are available and can be used for automated materials characterization and ore microscopy.

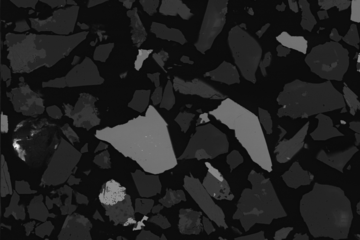

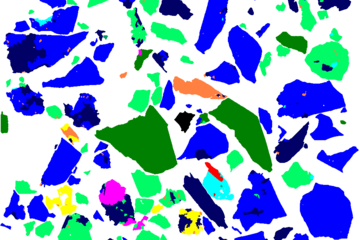

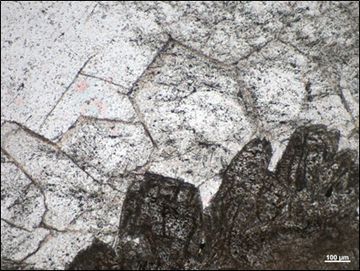

Embedding

Solid materials (e.g. ores, metals, ceramics) with a particle size up to 5,000 µm are embedded in epoxy. After curing the sample block is grinded and polished. Possible fields of application are automated materials characterization and ore microscopy. Polished sample blocks with diameters 25 mm, 25.4 mm (1 inch), 30 mm and 40 mm can be chosen.

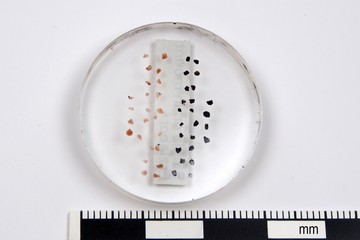

Single grain embedding

Several single grains or particles with sizes up to 100 µm are embedded in epoxy. After curing the sample block is grinded and polished. Important areas of application are, in addition to automated materials characterization, in situ analysis using electron probe micro analysis (EPMA), laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS) as well as in situ dating methods. Polished sample blocks with diameters 25 mm, 25.4 mm (1 inch), 30 mm and 40 mm are available.

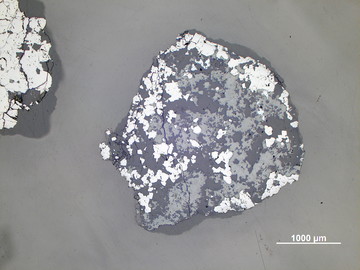

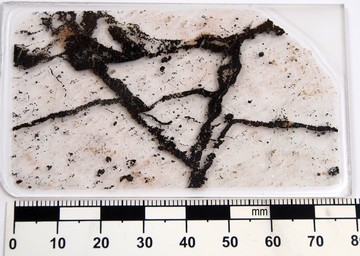

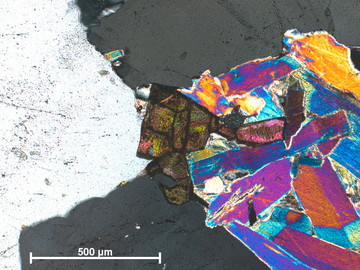

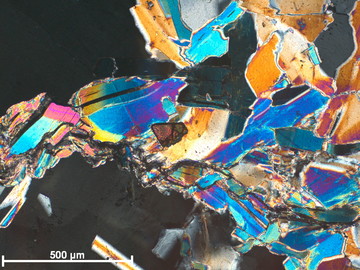

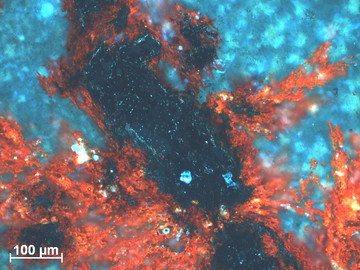

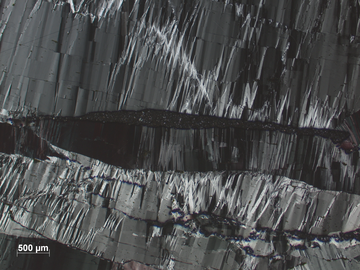

Thick and thin sections

Polished sections of rock material are prepared to your desired thickness (> 20 µm). A slice is cut from a piece of rock, trimmed, grinded, and bond with epoxy to a glass slide. After second trimming the specimen is grinded and polished. The main fields of application are reflected and transmitted light microscopy studies, automated materials characterization as well as cathodoluminescence microscopy. Available size formats are: 28 x 48 mm, 48 x 56 mm and 48 x 84 mm.

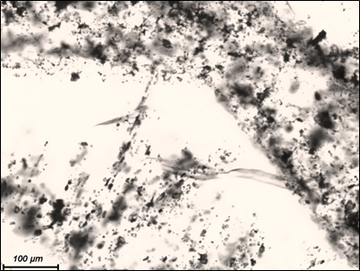

Doubly Polished Wafers

Doubly polished wafers of rock material with different thicknesses (prepared to your desired thickness) are fixed on a glass slide but can be demounted with acetone. The wafers are grinded and polished on both sides. The available size format is 28 x 48 mm. This wafers can be used in fluid inclusion studies.