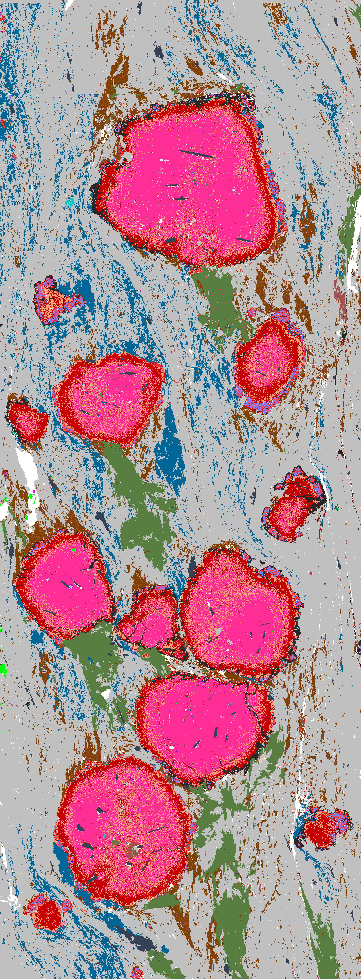

Ores

Processing products (concentrates, intermediates, tailings)

Recycling materials

Environmentally relevant materials (e.g., tailings, re-mining)

Today, automated materials characterization techniques are applied to environmental rehabilitation and re-mining. MLA and QEMSCAN analyses can be used to characterize tailings material with regard to potential pollutants and valuable residuals. The recognition of environmentally relevant mineral associations, e.g. containing penalty elements, is of particular importance.

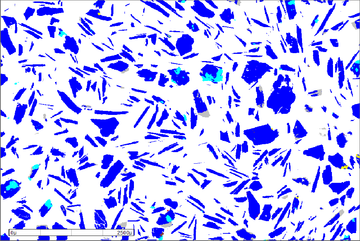

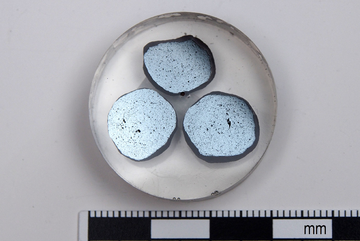

Glass

Automated materials characterization is used to detect and identify compositional impurities in special glasses with high purity requirements.

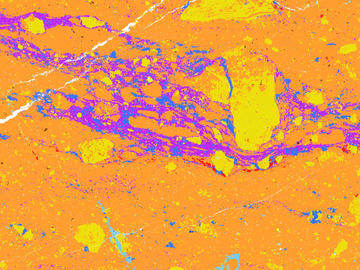

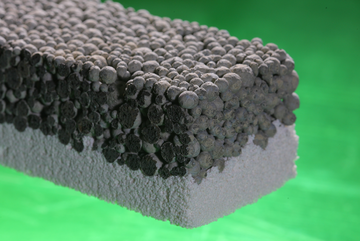

Ceramics

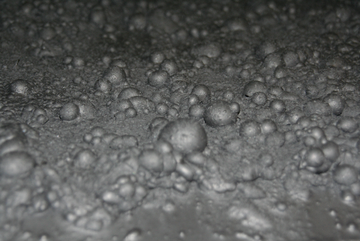

In the ceramic industry, the material characterization is used for quality control. Both the material structures (e.g. in respect of agglomerate formation) as well as intergrowths of phases are evaluated to ensure high quality products.

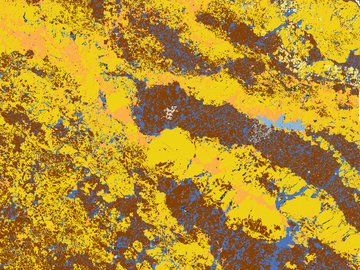

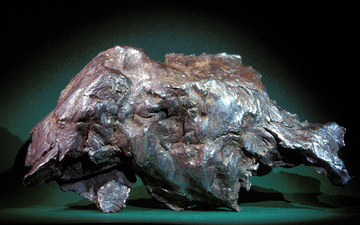

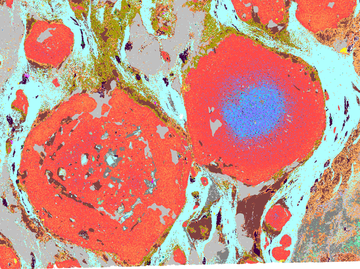

Metals and alloys

Semiconductor materials

The automated material characterization of semiconductor materials is used for quality control and for the detection and identification of critical impurities.

Building materials

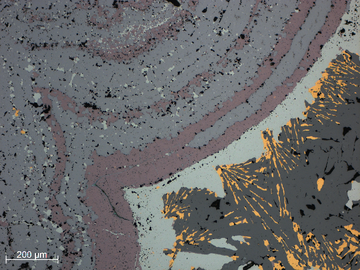

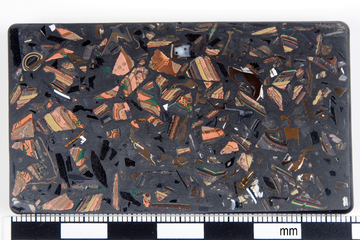

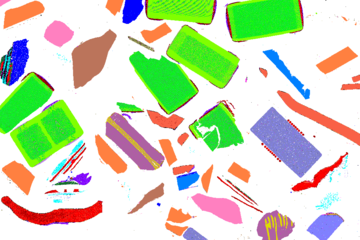

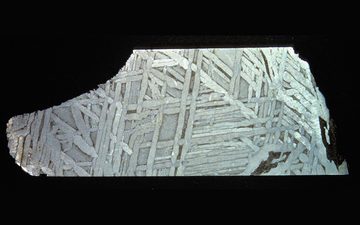

Rocks and sediments

ERZLABOR analyzes solid as well as granular materials. All three rock groups, magmatic, metamorphic as well as sedimentary rocks are analyzed with regard to their quantitative mineralogy. Furthermore, minor and trace minerals are identified and mapped.